Mastering Success: The Art of Pre Task Plan Construction

Kind Reader, pre task plan construction is an essential process in any construction project. It involves creating a step-by-step plan that outlines each task and identifies the potential hazards associated with each one. The aim is to identify and mitigate risks before work commences, ensuring that the construction site is safe for workers and any other parties involved. This plan is crucial for ensuring that the construction project is completed efficiently and effectively, without any accidents or injuries.

Benefits of Pre-Task Plan Construction

Pre-task plan construction is a crucial process that can prevent accidents and incidents from occurring in the workplace. It is a proactive approach that helps identify and mitigate potential hazards before work begins. Here are some of the benefits of pre-task plan construction:

Improved Safety

The most important benefit of pre-task plan construction is improved safety. By identifying hazards and mitigating risks before work begins, workers can avoid accidents and injuries. With a solid pre-task plan in place, workers are better equipped to handle any unexpected situations that may arise during the job.

Efficiency and Productivity

Pre-task plan construction can improve efficiency and productivity. By identifying the proper tools and equipment needed, workers can complete the job more quickly and efficiently. In addition, by eliminating potential hazards and risks, workers can focus on the task at hand without worrying about safety concerns.

Steps in Pre-Task Plan Construction

The pre-task plan construction process involves several steps to ensure the safety of the workers and the surrounding environment. Here are the steps:

Identify and Assess Hazards

The first step in pre-task plan construction is to identify and assess hazards. This includes identifying any potential safety risks or hazards that may be present in the work area. The assessment should consider the nature of the work, the tools and equipment needed, and the environmental factors that may affect the job.

Determine Control Measures

After identifying and assessing the hazards, the next step is to determine the control measures. This involves implementing strategies to mitigate or eliminate the risks. This may include engineering controls, administrative controls, or personal protective equipment.

Communicate and Implement Plan

Once the control measures have been determined, the pre-task plan should be communicated to the workers. The implementation of the plan should be clearly outlined, and all workers should be informed of their roles and expectations during the job.

Monitor and Review Plan

The final step is to monitor and review the pre-task plan. This involves ensuring that the control measures are effective and identifying any areas for improvement. The plan should be reviewed regularly to ensure that it remains effective, and any changes should be communicated to the workers.

Importance of Pre Task Plan Construction

Pre task plan construction is an important step for ensuring safety and efficiency in any task. It is particularly crucial in high-risk industries such as construction, mining, and manufacturing. Not only do pre task plans ensure that all workers are adequately prepared and equipped for the job, they also help identify potential hazards and create strategies to mitigate them.

Identifying Hazards

One of the key benefits of pre task plan construction is that it requires a thorough evaluation of potential hazards associated with the task. This process helps ensure that all possible risks are identified before work begins, and that workers are aware of the proper measures to take to avoid or mitigate them. By identifying hazards in advance, the likelihood of accidents or injuries is greatly reduced.

Improving Efficiency

Pre task plans help ensure that all workers are properly equipped and prepared for the task at hand. This includes having the necessary tools, materials, and safety equipment on hand, as well as ensuring that all workers have the necessary training and certifications. By being adequately prepared, workers are able to complete the task more efficiently and with higher quality results.

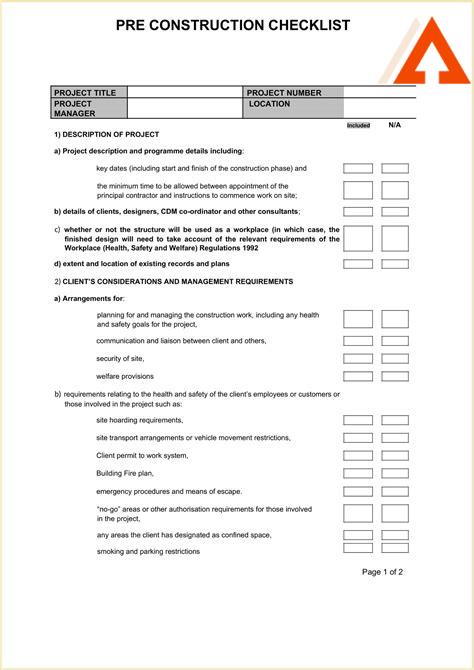

| No | Information |

|---|---|

| 1 | The purpose of pre task plan construction is to identify potential hazards and controls for a specific task. |

| 2 | The pre task plan should be developed by the people who will be performing the task. |

| 3 | The pre task plan should be reviewed and approved by a supervisor or safety professional. |

| 4 | The pre task plan should include a description of the task, potential hazards, and controls to mitigate those hazards. |

| 5 | The pre task plan should also include any required personal protective equipment (PPE), tools, or equipment. |

| 6 | The pre task plan should be communicated to everyone involved in the task. |

| 7 | The pre task plan should be reviewed and updated as needed based on changing conditions or new hazards that arise during the task. |

The Importance of Pre Task Plan Construction

Pre task plan construction is an integral part of any project. This process involves identifying potential hazards and developing a plan to address them. The pre task plan ensures that everyone involved in the project understands the risks and how to mitigate them. There are several reasons why pre task plan construction is essential.

Ensuring Safety

The primary reason for pre task plan construction is to ensure the safety of everyone involved in the project. By identifying potential hazards and developing a plan to address them, the risk of accidents and injuries can be significantly reduced. This is especially important in high-risk industries such as construction, manufacturing, and mining.

Meeting Legal Requirements

Many industries have regulatory requirements for pre task plan construction. Employers must comply with these regulations to avoid penalties and legal action. In addition, pre task plans can also be used as evidence of due diligence in the event of an accident or injury.

Pre Task Plan Construction: Steps Involved

In order to construct an efficient pre task plan, there are certain steps that need to be taken. These steps help ensure that all aspects of the project are taken into consideration, and the plan is comprehensive and effective.

Step 1: Identify the Task

The first step in constructing a pre task plan is identifying the task that needs to be completed. This involves understanding the scope of the project, the risks involved, and any other relevant information.

Step 2: Analyze the Task

Analyzing the task involves breaking it down into smaller, manageable parts. This helps identify potential hazards and risks associated with each sub-task.

Step 3: Develop Control Measures

Once the hazards and risks have been identified, control measures need to be developed to mitigate them. These measures could include engineering controls, administrative controls, or personal protective equipment.

Step 4: Communicate the Plan

Once the plan has been developed, it needs to be effectively communicated to all members of the project team. This includes ensuring that everyone involved understands their role in the plan and what is expected of them.

Step 5: Implement the Plan

Implementing the pre task plan involves putting the plan into action. This could include scheduling tasks, setting up work areas, and ensuring that all necessary equipment and materials are available.

Step 6: Monitor the Plan

The pre task plan needs to be continuously monitored to ensure that it remains effective. This involves regularly assessing the hazards and control measures and making any necessary adjustments.

Step 7: Evaluate the Plan

Finally, the pre task plan needs to be evaluated once the project is complete. This helps identify what worked well and what could be improved for future projects.

The process of developing a pre task plan is critical to ensuring the safety and success of any project. By following these steps, you can construct a plan that effectively addresses potential hazards and risks and helps you complete your task efficiently.

Pre-task plan construction principles

During pre-task planning, meeting specific principles is essential for ensuring the process meets its objective. It identifies hazards, assessments, and ensures risks are eliminated before work commences. Here are some principles of pre-task plan construction:

Principle 1: Defining the Health and Safety Roles in PTP

Before drawing a pre-task plan, it’s crucial to identify and define the roles of each person involved. List the roles and assign responsibilities to each person. Roles may include health, safety, equipment operator, work leader, and emergency response team.

Principle 2: Identify Potential Hazards

Identifying potential hazards is the backbone of pre-task planning. When identifying hazards, consider equipment failures, unstable work surfaces, weather conditions, etc. Note the risks and document them in a hazard ID log or form before coming up with ways to control them.

Principle 3: Establish Safety Controls

Design strategies and safety controls that help mitigate each possibility of risk and hazard that was identified. Use different methods such as tools, PPE, and equipment to safeguard against potential risks.

Principle 4: Communicate the plan

Ensure every participant involved comprehends the pre-task plan. Use briefs to communicate or demonstrate the plan. Make sure everyone comes up with a suitable solution for each identified hazard.

Principle 5: Review and Retain PTP

After pre-task plan execution, it’s essential to review the plan. Review accomplishments and failures or lessons learned from the operation. Use it as a reference for future similar jobs.

Principle 6: Renewing/Retrofit

When reviewing the pre-task plan, seek improvements, identify mistakes and errors in the procedure. Analyze hazards that did not occur beforehand and draft up new plans that can further eliminate those risks. Also, examine procedures that did not provide sufficient control and fix them, so it can be effective in the future.

Principle 7: Establish a culture of safety

Instituting a culture of safety involves promoting awareness of accident prevention. Conduct safety training sessions and cultivate an environment of safety that prioritizes the welfare of employees. Always include safety in meetings, morning briefings, and before JSA (Job Safety Analysis) to decrease risks and promote pre-task plan construction.

Pre-task plan construction benefits

Creating a pre-task plan before starting a project brings multiple benefits that can help achieve success throughout the entire project. In this section, we will discuss the benefits of pre-task plan construction and how it can help improve project outcomes.

Improved safety on site

One of the benefits of pre-task plan construction is improved safety on site. By identifying potential hazards and risks before starting the project, safety measures can be put in place to protect workers and prevent accidents from happening. This can ultimately save time, money, and lives. With a pre-task plan, every worker knows the safety procedures to follow, reducing the likelihood of accidents happening on site.

Efficient use of resources

Another benefit of pre-task plan construction is efficient use of resources. By planning ahead, a team can determine the exact resources needed to complete a project and when they will be required. This can help avoid waste of resources, including time, money, and materials. A pre-task plan prompts project teams to consider efficient ways to use resources, which is a key factor in executing a project successfully. With efficient use of resources, projects are often completed within the deadline and within budget.

Benefits of Pre Task Plan Construction

Pre task plan construction offers several benefits for both employers and workers. Here are some of the benefits of pre task plan construction:

Efficient Task Execution

When workers know exactly what has to be done, how to do it, and what equipment is required, the tasks can be executed smoothly and efficiently. Pre task plan construction helps workers understand the scope of the task, and what is expected of them. This reduces the chances of confusion and delays, which can cause frustration for workers and ultimately lead to project cost overruns.

Improved Safety Standards

Pre task plan construction is a crucial component of safety planning. It helps identify potential hazards and develop risk elimination or mitigation measures. When workers are clear about how to perform a task safely, they can take the necessary precautions and reduce the risk of accidents or injuries. Pre task plan construction helps in achieving the target of zero harm, which is the ultimate goal for any work site.

Increased Productivity

When tasks are executed efficiently and safely, workers can focus on producing high-quality work in a timely manner. Productivity is increased when all team members understand their roles and responsibilities, and are clear about the tasks they need to complete.

Better Communication

Pre task plan construction involves discussions among team members. When workers communicate effectively, they are able to resolve issues or difficulties in real-time, without waiting for problems to escalate. Effective communication leads to better collaboration and team performance.

| No | LSI Keywords |

|---|---|

| 1 | Pre task planning benefits |

| 2 | Efficient task execution |

| 3 | Improved safety standards |

| 4 | Increased productivity |

| 5 | Better communication |

Source: OSHA

Frequently Asked Questions (FAQ) on Pre Task Plan Construction

This FAQ aims to provide answers to common questions, doubts, and concerns related to pre task plan construction. We hope it helps you to carry out your tasks safely and effectively.

1. What is a pre task plan?

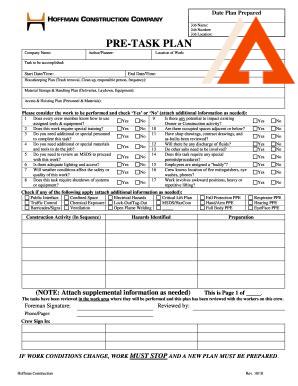

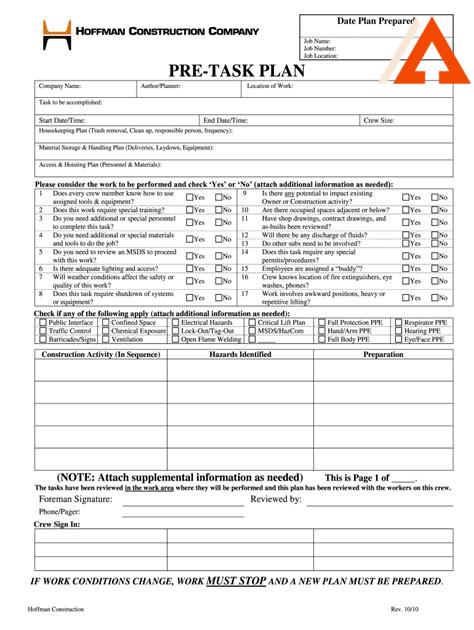

A pre task plan is a written document that outlines the steps, methods, risks, and safety measures involved in a task or project. It helps to identify hazards, assess risks, and plan for safety controls before starting any work.

2. Why is pre task planning important?

Pre task planning is important because it helps to identify potential hazards and risks, and plan for safety controls before starting any work. It reduces the chances of accidents, injuries, damages, or delays. It ensures that all workers involved in the task or project understand their roles, responsibilities, and safety measures. It also helps to comply with legal and regulatory requirements.

3. Who is responsible for pre task planning?

The person or team responsible for the task or project is usually responsible for pre task planning. It could be the supervisor, manager, contractor, or any designated person with the relevant knowledge, experience, and authority. It is important to involve all stakeholders, including workers, in the pre task planning process.

4. How do you prepare a pre task plan?

To prepare a pre task plan, you need to identify the task or project, its objectives, methods, risks, and safety controls. You need to assess the potential hazards and risks, and plan for safety controls such as personal protective equipment, training, communication, emergency response, and monitoring. You need to document the pre task plan and communicate it to all relevant stakeholders.

5. What should be included in a pre task plan?

A pre task plan should include the task or project description, objectives, methods, hazards, risks, control measures, communication, emergency response, monitoring, and signature of the responsible person. It should be documented in writing and communicated to all relevant stakeholders.

6. When should you prepare a pre task plan?

You should prepare a pre task plan before starting any new task or project or when there are changes in the task or project that could affect safety. It is also advisable to review and update the pre task plan regularly to ensure that it is still relevant and effective.

7. How often should you review and update a pre task plan?

You should review and update the pre task plan regularly, depending on the complexity, duration, and frequency of the task or project. At a minimum, you should review and update the pre task plan every time there are changes to the task or project that could affect safety or when there are changes to legal or regulatory requirements.

8. Who should approve the pre task plan?

The pre task plan should be approved by the responsible person or team and communicated to all relevant stakeholders, including workers, before starting any work. It is important to ensure that all workers understand and follow the pre task plan.

9. How do you ensure that all workers understand and follow the pre task plan?

You can ensure that all workers understand and follow the pre task plan by providing training, communication, and supervision. You need to explain the pre task plan to all workers involved in the task or project and answer any questions or concerns they may have. You need to ensure that all workers have the required skills, knowledge, and equipment to carry out the task safely and effectively. You need to monitor the work to ensure that it is following the pre task plan.

10. What happens if the pre task plan is not followed?

If the pre task plan is not followed, it could lead to accidents, injuries, damages, or delays. It could also lead to legal or regulatory non-compliance. It is therefore important to ensure that all workers understand and follow the pre task plan, and that there are consequences for non-compliance.

11. What should you do if you identify hazards or risks during the task?

If you identify hazards or risks during the task, you should stop the task immediately and assess the situation. You should review the pre task plan and update it if necessary. You should communicate the changes to all relevant stakeholders and implement the new safety controls before resuming the task. You should also report the incident or near-miss to the responsible person or team.

12. How do you document and store the pre task plan?

You should document and store the pre task plan in a safe and secure location that is accessible to all relevant stakeholders. You can use electronic or hard-copy format, as long as it is legible and up-to-date. You should also keep records of the pre task plan, including any changes or updates, and retain them for the required period.

13. What is the difference between a pre task plan and a safety plan?

A pre task plan is a specific plan for a task or project that outlines the steps, methods, risks, and safety measures involved. A safety plan is a more general plan that outlines the overall safety policies, procedures, resources, and objectives of an organization. Both plans are important for ensuring safety, but they serve different purposes.

14. What is a toolbox talk?

A toolbox talk is a short safety meeting that is held before starting a task or project. It aims to communicate the pre task plan, hazards, risks, and safety controls to all workers involved in the task. It also provides an opportunity for workers to ask questions or raise concerns about safety.

15. How do you conduct a toolbox talk?

To conduct a toolbox talk, you need to gather all workers involved in the task or project, provide them with the pre task plan, and explain the hazards, risks, and safety controls. You need to encourage workers to ask questions or raise concerns about safety, and address them appropriately. You need to document the toolbox talk and retain the records for the required period.

16. What are some common hazards and risks in pre task planning?

Common hazards and risks in pre task planning include physical hazards, such as falls, slips, and trips; chemical hazards, such as exposure to hazardous substances or gases; biological hazards, such as exposure to pests or infectious agents; and ergonomic hazards, such as repetitive motion or awkward postures. Other hazards and risks may depend on the specific task or project.

17. What are some common safety controls in pre task planning?

Common safety controls in pre task planning include personal protective equipment, such as gloves, goggles, or respirators; training, such as safety procedures or emergency response; communication, such as signs, signals, or alarms; emergency response, such as evacuation or first-aid; and monitoring, such as inspections or audits. Other safety controls may depend on the specific task or project.

18. What is a job safety analysis?

A job safety analysis is a process of identifying and analyzing the hazards and risks involved in a specific job or task. It involves breaking down the job into steps, identifying the hazards and risks at each step, and planning for safety controls to prevent or mitigate the hazards and risks. It is a useful tool for pre task planning.

19. What is a hazard assessment?

A hazard assessment is a process of identifying and analyzing the hazards and risks involved in a workplace, task, or project. It involves evaluating the potential sources, causes, and effects of hazards and risks, and planning for safety controls to prevent or mitigate the hazards and risks. It is a useful tool for pre task planning and overall safety management.

20. What is the role of workers in pre task planning?

Workers have a critical role in pre task planning because they are the ones who carry out the task or project. Workers need to be involved in the pre task planning process, understand the pre task plan, follow the safety controls, and report any hazards or risks they encounter. Workers also need to be trained and provided with the required personal protective equipment and resources to carry out the task safely and effectively.

21. What is the role of supervisors in pre task planning?

Supervisors have a critical role in pre task planning because they are responsible for ensuring that the task or project is carried out safely and effectively. Supervisors need to ensure that the pre task plan is prepared, communicated, and followed by all relevant stakeholders. Supervisors also need to provide training, supervision, and resources to workers, and report any incidents or near-misses to the responsible person or team.

22. What is the role of managers in pre task planning?

Managers have a critical role in pre task planning because they are responsible for ensuring that the overall safety policies, procedures, and resources of the organization are aligned with the task or project objectives. Managers need to ensure that the pre task plan is prepared, communicated, and followed by all relevant stakeholders. Managers also need to provide the required resources, support, and feedback to supervisors and workers, and report any trends or issues related to safety to the higher management.

23. What is the role of contractors in pre task planning?

Contractors have a critical role in pre task planning because they are responsible for ensuring that the task or project is carried out safely and effectively. Contractors need to ensure that they have the required skills, knowledge, and equipment to carry out the task, and that they comply with legal and regulatory requirements. Contractors also need to collaborate with the responsible person or team and communicate any constraints or challenges related to safety.

24. What is the consequence of non-compliance with pre task planning?

The consequence of non-compliance with pre task planning could be severe, such as accidents, injuries, damages, or delays, or legal and regulatory non-compliance. It could also affect the reputation, morale, and productivity of the organization. It is therefore important to ensure that all workers, supervisors, and contractors understand and follow the pre task plan, and that there are consequences for non-compliance.

25. How do you evaluate the effectiveness of pre task planning?

To evaluate the effectiveness of pre task planning, you need to measure the outcomes and impact of the plan, such as the incidence of accidents, injuries, damages, or delays, and compare them to the expected results. You also need to gather feedback from workers, supervisors, and contractors about the pre task plan, and identify any areas for improvement. You need to review and update the pre task plan regularly, based on the evaluation results.

Learn how to develop a pre-task plan for construction projects to ensure that every worker knows the hazards involved in a particular task and the steps to avoid, minimize, or control those hazards.

Until We Plan Again

Kind Reader, it’s been a pleasure to share with you the concept and benefits of Pre Task Plan Construction in a relaxed English language. Remember, PTPC is not about creating more paperwork but empowering workers to put safety first and avoid accidents. So, let’s continue to implement PTPC in our every task and make our workplace safer for everyone. Thank you for taking your time to read this article, and please visit us again, soon.