Revolutionize Your Construction Projects with Innovative Construction Pads

Kind Reader, construction pads are an essential component when it comes to building structures and infrastructure. These thick and durable materials are designed to provide a stable and secure base for heavy machinery and equipment during construction projects. With their ability to distribute weight evenly and reduce the risk of damage to the underlying surface, construction pads play a crucial role in ensuring the success and safety of even the most complex building projects.

Construction Pads for Heavy Equipment

Construction pads are crucial for the operation of heavy equipment in construction projects. These pads, otherwise known as outrigger pads, crane pads, and cribbing blocks, provide a stable base for heavy equipment to operate on. Without construction pads, the outriggers or tracks of heavy machinery would sink into unstable soil, potentially causing damage to the machine and putting the safety of the operators at risk. Construction pads are typically made from durable materials such as wood, composite materials, or high-density plastic, and they come in various sizes and thicknesses to accommodate different types of machinery and terrains.

The Importance of Using Construction Pads

Using construction pads is essential for maintaining a safe and efficient work environment on construction sites. The stability provided by construction pads reduces the risk of equipment tipping over, which could potentially result in damage to the machinery or injury to the operator. In addition, the use of construction pads minimizes the environmental impact of construction, as they help prevent soil erosion and damage to grass and landscaping.

The Different Types of Construction Pads

There are different types of construction pads available on the market, and each type is suitable for specific applications and construction equipment. Some of the most common types of construction pads include:

| No | Type of Construction Pad | Description |

|---|---|---|

| 1 | Wooden Construction Pads | Wooden construction pads are made from hardwood or softwood lumber and are popular for their durability and cost-effectiveness. |

| 2 | Composite Construction Pads | Composite construction pads are made from a combination of materials such as plastic and rubber. These pads are lightweight and easy to transport. |

| 3 | Plastic Construction Pads | Plastic construction pads are made from high-density polyethylene and are designed for heavy-duty use. These pads are long-lasting and resistant to water and chemicals. |

DIY Construction Pads for Do-It-Yourselfers

Do-it-yourselfers can create construction pads using materials that are found in most hardware stores. Creating these pads from scratch is a cost-effective way to ensure that the equipment being used is stable and safe. For those who would like to make their own construction pads, there are several tips that they can follow:

Materials Required for DIY Construction Pads

The following materials are necessary for making DIY construction pads:

- Pressure-treated lumber

- Drill and saw

- Measuring tape and pencil

- Bolts and nuts

Steps for Making DIY Construction Pads

The process for creating construction pads is relatively straightforward:

- Measure and cut the pressure-treated lumber to the desired size.

- Drill holes in the center of each wooden pad where the bolts and nuts will be placed.

- Bolt the wooden pads together to create a large pad.

- Place the pads under the machinery.

It is important to note that the size and thickness of the DIY construction pads will depend on the equipment being used and the terrain being operated on. For best results, it is recommended that you consult with a professional or manufacture the pads per your equipment’s requirements.

Types of Construction Pads

Construction pads come in different types and sizes, each suited for a particular application. Choosing the right type of construction pad is crucial in ensuring that your equipment is protected and you have a safe working environment. Below are some of the common types of construction pads:

1. Mobile Construction Pads

These construction pads are designed for mobile equipment and work perfectly on rough terrain. They come in a variety of sizes and may be made of different materials, including wood, metal, or composite material. They are easy to install, making them ideal for short-term projects.

2. Crane Pads

Crane pads are used to support the crane outriggers, stabilize the crane, and prevent it from sinking into the ground. They are available in different shapes and sizes and may be made of wood, steel, or composite material. The size and thickness of the crane pad depend on the weight of the crane, the soil conditions, and the terrain.

3. Heavy Equipment Pads

Heavy equipment pads are designed to support large machinery and are an essential part of many construction sites. They are often made of durable composite materials and are much stronger than rubber or wooden mats. These pads can be customized to fit the unique needs of your equipment. They may also have additional features, such as locking mechanisms, for added safety.

4. Pipeline Pads

Pipeline pads are used to protect pipelines from damage and provide a flat, stable surface around the pipeline. They are typically made of wood or composite material and are easy to install and remove. Pipeline pads help prevent soil erosion, offer a level working surface, and protect the pipeline from heavy equipment movements.

5. Temporary Roadway Pads

Temporary roadway pads are used to protect the ground and provide a sturdy surface for heavy equipment to move on. They are ideal for situations where access to the site is limited or where the work needs to be done over a large area. They can be installed quickly and can be removed once the work is complete.

6. Steel Mats

Steel mats are heavy-duty, durable mats designed to support heavy equipment and provide a stable working surface. They are ideal for use in oil and gas projects, pipeline construction, and other heavy-duty applications. They are easy to transport and can be customized to fit the unique needs of your project.

7. Composite Mats

Composite mats are lightweight, durable mats made of composite materials that are strong enough to support heavy equipment. They are easy to install and can be used in a wide range of applications, including oil and gas projects, pipeline construction, and other heavy-duty applications. They can be customized to fit the unique needs of your project.

| No | Important Information about Construction Pads |

|---|---|

| 1 | Construction pads provide a stable base for temporary structures. |

| 2 | These pads can be made from various materials such as gravel, crushed stone, asphalt, and concrete. |

| 3 | They are commonly used for mobile homes, site offices, and storage containers. |

| 4 | Construction pads need to be levelled and compacted properly to provide a firm surface. |

| 5 | The size and thickness of the construction pad depend on the weight and size of the structure it supports. |

| 6 | Permits may be required from local authorities before installing a construction pad. |

| 7 | Maintenance of construction pads may include filling in sinkholes, repairing cracks, and adding new layers of material. |

Types of Construction Pads

Construction pads have different types, each with a unique purpose. The following are the various types of construction pads:

Rubber Pads

Rubber pads are made from heavy-duty rubber that provides excellent stability and support. They are ideal for use in construction sites where heavy machinery is used. The rubber material absorbs vibrations and noise, minimizing their effects on the environment and surrounding people. Rubber pads are also resistant to slippage, chemicals, and other types of damage, making them ideal for long-term use.

Plastic Pads

Plastic pads are designed to provide strong support for heavy machinery. They are made from high-density polyethylene, which makes them lightweight and durable. The plastic material is resistant to chemicals and other types of damage, making it well-suited for outdoor use. Plastic pads are also easy to install and remove, making them ideal for projects that require frequent machine movement.

Composite Pads

Composite pads are a combination of rubber and plastic materials, providing a balance of stability and durability. The rubber and plastic parts are molded together, creating a single, sturdy pad. Composite pads are well-suited for use in harsh environments, where extreme temperatures and heavy loads are common. They are also resistant to chemicals, moisture, and other environmental factors.

Wooden Pads

Wooden pads are made from hardwood, such as oak or maple. They provide a natural, sturdy base for heavy machinery and equipment. Wooden pads are ideal for use in urban environments, where noise and vibrations from heavy machinery are a concern. They are also easy to install and remove, making them suitable for projects that require frequent machine movement.

Metal Pads

Metal pads, also called steel pads, are made from heavy-duty steel. They are designed to provide strong support for heavy machinery and equipment. Metal pads are ideal for use in rough terrain, where stability is essential. They are also resistant to chemicals, moisture, and other environmental factors, making them suitable for long-term use.

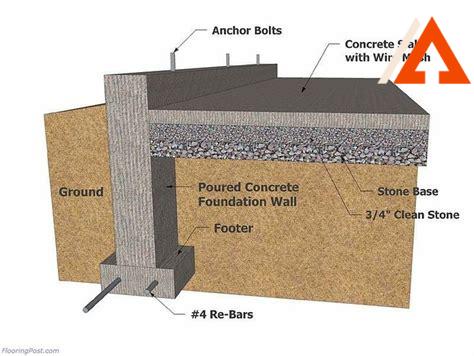

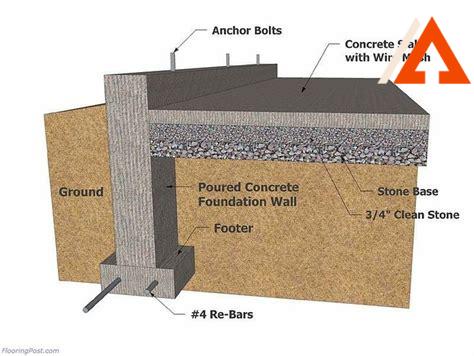

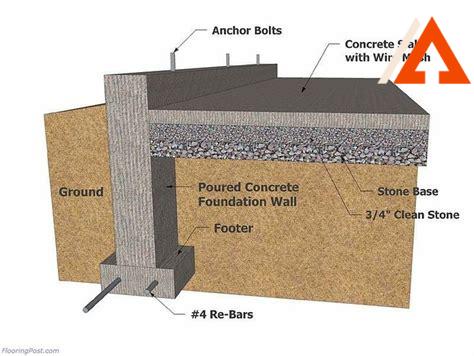

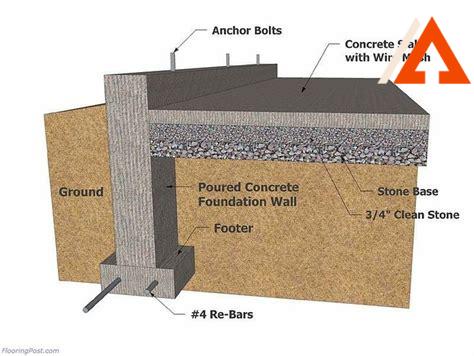

Concrete Pads

Concrete pads are a traditional option for supporting heavy equipment and machinery. They are made from reinforced concrete, providing a sturdy base. Concrete pads are ideal for use in permanent installations and may be bolted to the ground for added stability. They are also resistant to chemicals, moisture, and other environmental factors, making them suitable for long-term use.

Hybrid Pads

Hybrid pads combine two or more materials, creating a unique solution for specific needs. For example, a hybrid pad may combine rubber and concrete, providing a balance of stability and durability. Hybrid pads are well-suited for complex projects that require a customized solution.

Types of Construction Pads

Construction pads are available in different types that cater to different needs and unique features. Different pads function differently, but they all aim to protect the surface below. Below are some types of construction pads:

1. Foam Pads

Foam pads are made of a soft and lightweight material that makes them perfect for preventing surface scratches while lifting heavy machinery. These pads also come in handy when you require something to soften landing spots for heavy objects. They offer an entirely cushioned support to anything with substantial weight thus preventing floor damage.

2. Rubber Pads

Rubber pads are highly flexible and sturdy, and they work perfectly for heavy equipment that needs to be kept in place. Rubber pads come in different shapes, sizes, and thicknesses, depending on the machinery they accommodate. They are ideal for temporary laying on hard surfaces and can be easily replaced once worn out.

3. Plastic Pads

Plastic pads are durable, resistant to wear and tear, and offer a stable and long-lasting solution to many construction projects. They are designed to protect high-end, delicate floors from severe damage during construction and heavy machinery transfer. They can be used both at the interior and exterior of a site and provide an ideal surface that will prevent damage to the surface below.

4. Steel Pads

Steel pads are made of high tensile strength and are specifically designed to work in heavy industrial and construction equipment settings. These pads come in both square and round shapes, and the user can choose appropriately depending on the machinery. Steel pads are meant to serve a more extended period and are much durable than other types of pads.

5. Sand Laminated Mats

Sand laminated mats are made of hardwood, covered with sand. These mats offer a barrier between the ground and the machinery reducing any considerable damage to the surface below. They are more rugged than traditional hardwood mats and offer better traction for heavy-duty machinery.

6. Composite Mats

Composite mats are made from a combination of materials that offer durability and strength. These mats are quite sturdy, yet flexible and can be transported easily. They are ideal for harsh, rugged terrain as well as for sensitive environments like sod installation, landscaping, and sports arenas.

7. Access Mats

Access mats are designed for temporary or permanent installation of roadways, drill pads, crane pads, and work platforms. They are also useful in environmentally sensitive areas that require soil stabilization. Access mats come in different sizes and shapes depending on the site needs and equipment to support, and they can be made from hardwood, steel, or composites.

Benefits of Using Construction Pads

Construction pads have numerous benefits when used during a construction project. Here are some of the advantages of using construction pads:

1. Protection of Surfaces

Construction pads are designed to protect surfaces from scratches, chips, and other damages that may occur during the construction process. These pads are usually made of high-density materials that can withstand heavy loads, making them ideal for use under heavy equipment and machinery. By using construction pads, surfaces can be protected from damage, which can save money and time in the long run.

2. Increased Safety and Stability

Construction pads can also improve safety and stability during a construction project. When heavy equipment is placed on a construction pad, it provides a stable base for the equipment, reducing the risk of accidents and injuries. Additionally, construction pads can prevent equipment from sinking into the ground, which can cause instability and increase the risk of accidents.

Use of Construction Pads for Industrial and Commercial Applications

Construction pads are widely used in industrial and commercial applications where heavy machinery and equipment are used. The pads help in stabilizing the machines and protecting the floor from damages caused by the machines. These pads are especially useful in construction sites, factories and warehouses where heavy machinery and equipment are constantly in use.

Construction pads for construction sites

Construction sites require a lot of heavy machinery and equipment for construction work such as excavators, bulldozers and cranes. These machines can cause damages to the concrete and asphalt surfaces. Construction pads are therefore used to provide a stable surface for such machines and prevent the surface from getting damaged. Additionally, construction pads provide a level surface for the machines to operate on, which greatly improves their efficiency.

Construction pads for factories and warehouses

In factories and warehouses, construction pads are used to protect the floor from damages caused by heavy machinery and equipment. These pads help in absorbing the vibrations and impact of the machines, which would otherwise cause the floors to crack and get damaged. The pads also provide a non-slip surface for the machines, which improves their safety.

| No | Examples of industrial and commercial applications of construction pads |

|---|---|

| 1 | Construction sites |

| 2 | Factories and warehouses |

| 3 | Airports and seaports |

Construction pads for airports and seaports

Airports and seaports require heavy machinery and equipment for cargo handling and transportation. The use of construction pads provides stability for the machines and protects the surface from damages caused by the machines. Additionally, the pads help in reducing the noise pollution caused by the machines, which creates a more conducive working environment for the workers.

Types of Construction Pads

Construction pads have different types that can be used for specific purposes. Here are the types of construction pads:

1. Polyurethane Pads

Polyurethane pads are made from synthetic materials that have a high resistance to impact. These pads can be used for heavy-duty applications and are ideal for areas that experience constant traffic. Polyurethane pads are also resistant to abrasion and are easy to install.

2. Rubber Pads

Rubber pads are made from natural or synthetic rubber materials. They can absorb shock and vibration, making them suitable for applications that require high levels of noise and vibration reduction. Rubber pads also have a high resistance to chemicals and oils, making them ideal for use in industrial environments.

3. Neoprene Pads

Neoprene pads are made from a type of synthetic rubber that is resistant to water, UV rays, and weathering. They are ideal for applications that require high levels of water resistance, such as bridge or highway construction. Neoprene pads can also be custom-made to fit specific applications.

4. Cork Pads

Cork pads are made from natural cork materials that provide excellent thermal and acoustic insulation. They are suitable for use in applications that require high levels of temperature resistance and energy absorption. Cork pads are also resistant to moisture and insects, making them ideal for outdoor use.

5. Steel Pads

Steel pads are made from steel materials and are commonly used in heavy machinery or equipment applications. They are highly durable and can withstand extreme pressure and weight, making them ideal for industrial applications. Steel pads also have a low coefficient of friction, reducing wear and tear on equipment.

6. Masonry Pads

Masonry pads are made from a mixture of concrete and other materials that provide high levels of compression and tensile strength. They are commonly used in masonry and construction applications and can be customized to fit specific requirements. Masonry pads can also be used for soundproofing and fire protection.

Construction Pads: Subtitle FAQ

Here are some frequently asked questions about construction pads to guide you.

1. What are construction pads?

Construction pads are platforms made from materials such as wood, plastic or steel that provide a level surface for working on during construction activities.

2. Why are construction pads used?

Construction pads are used to provide stability and a level surface for workers, heavy equipment, and construction materials, especially in areas with unstable ground or uneven terrain.

3. Can construction pads be customized?

Yes, construction pads can be customized to fit specific project requirements in terms of size, shape, and material.

4. What types of construction pads are available?

There are various types of construction pads, including steel, wood, and plastic construction pads, among others.

5. How are construction pads installed?

Construction pads are installed by ensuring the ground is level and stable before placing the pad on the ground. They may be fastened into position using stakes, bolts, or other fasteners.

6. Are construction pads safe?

Yes, construction pads are safe to use as long as they are installed correctly and used in accordance with manufacturer guidelines. Proper safety measures should also be taken to prevent accidents.

7. How long do construction pads last?

The lifespan of construction pads depends on the material used, how they are installed, and how well they are maintained. Steel construction pads can last for years while wood or plastic construction pads may need replacement more often.

8. What size construction pads are available?

Construction pads range in size from small pads to large ones that can accommodate heavy machinery and trucks.

9. Can construction pads be stacked?

Yes, construction pads can be stacked to provide additional height or to create platforms of varying heights to accommodate different construction activities.

10. What is the weight capacity of construction pads?

The weight capacity of construction pads varies depending on the size, material, and design of the pad. It’s important to check the weight capacity specification before using a pad.

11. Can construction pads be used on uneven ground?

Yes, construction pads can be used on uneven ground, but it’s important to ensure that the ground is stable and free from debris before installation.

12. How to maintain construction pads?

Construction pads should be cleaned and inspected regularly to remove any debris and to prevent damage. Any damaged pads should be replaced immediately.

13. Can construction pads be rented?

Yes, construction pads can be rented from construction equipment rental companies. This is an economical option for contractors who need construction pads for a short-term project.

14. What is the cost of construction pads?

The cost of construction pads varies depending on the size, material, and design of the pad. Steel construction pads tend to be more expensive than wood or plastic pads.

15. Are there any environmental concerns with using construction pads?

Construction pads made from wood or plastic may have environmental implications, such as deforestation or non-biodegradability. Companies should consider the environmental impact before choosing a pad material.

16. What are the benefits of using construction pads?

The benefits of using construction pads include improved safety, stability, and efficiency of construction operations, especially in challenging terrain.

17. How do I know which type of construction pad is suitable for my project?

The suitability of construction pads depends on the specific requirements of your project. Consulting with an experienced contractor or equipment rental company can help you determine the appropriate type of pad for your project.

18. What should I do if a pad becomes damaged?

If a pad becomes damaged, it should be removed from use immediately and replaced with a new one. This ensures that safety and stability are maintained on the construction site.

19. Are steel construction pads environmentally-friendly?

Steel construction pads are environmentally-friendly as they are recyclable and have a long lifespan. This reduces the amount of construction waste that goes into the environment.

20. Can I purchase used construction pads?

Yes, used construction pads may be available for purchase or rental. However, it’s essential to ensure that the pads are in good condition and meet safety standards before using them for construction activities.

21. Does the installation of construction pads require any special permits?

The installation of construction pads may require permits from local authorities, depending on the size and location of the construction site. It’s important to check with relevant authorities before installation.

22. Are construction pads suitable for heavy machinery?

Yes, construction pads are suitable for heavy construction equipment and trucks. However, it’s essential to ensure that the pad is appropriately sized and rated for the weight of the machinery.

23. What is the standard size of construction pads?

There is no standard size for construction pads as they come in various sizes and shapes. The size and shape of the pad should be chosen based on the specific requirements of the construction project.

24. How do I dispose of construction pads?

The disposal of construction pads depends on the material used. Steel pads may be recycled while wood or plastic pads may be disposed of in keeping with local waste disposal regulations.

25. Can I use construction pads for temporary structures?

Yes, construction pads can be used to provide stability for temporary structures such as tents or mobile homes. However, it’s important to ensure that the pad is appropriately sized and rated for the weight of the structure.

Looking for quality construction pads? Check out construction pads on Arpist.net to find the perfect solution for your construction needs.

Until next time, Kind Reader

As we conclude this article, we hope that you have gained valuable insights on what construction pads are and how they function. We know that construction activities can be overwhelming and even dangerous, but with construction pads, builders can keep their work areas safe and organized. Thank you for taking the time to read this article, we hope to see you again soon. Stay safe and keep learning!